“Coming up with names for all these fish would be a problem,” said James Civiello, manager of Shepherd of the Hills Hatchery in Branson.

Civiello was referring to the 1.4 million 2- to 11-inch trout currently in residence at the hatchery. He said Shepherd of the Hills produces the sleek, silver fish, as if from a cookie cutter stamp, month after month, year after year.

Shepherd of the Hills is one of 10 fish-rearing facilities in Missouri’s fish hatchery system. Conservation Department hatcheries raise and release fish by the millions, and not just trout. The state hatcheries’ product line ranges from channel catfish to paddlefish, from Topeka shiners to muskies.

It’s true that fish generally can reproduce on their own. Female fish lay eggs by the thousands, but they usually need that many. It’s a fish-eat-fish world underwater, and only a tiny fraction of young fish survive.

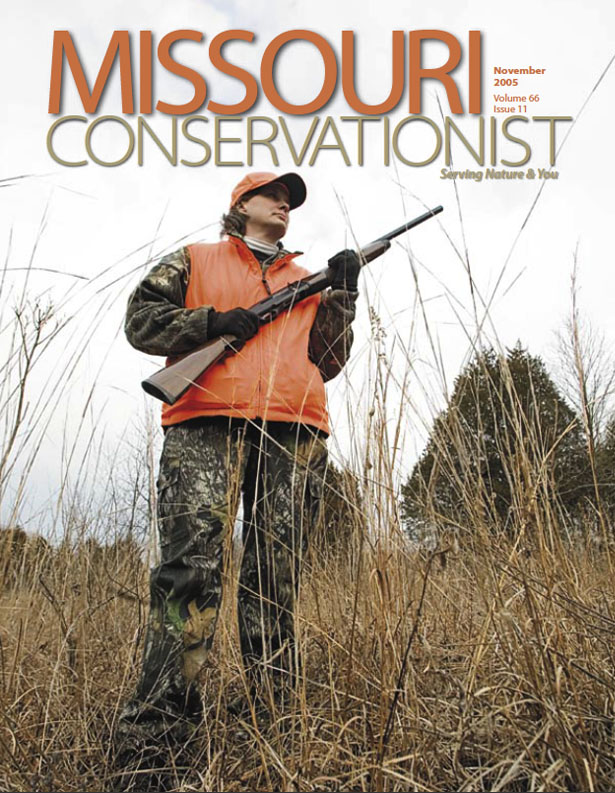

In most state lakes and streams, that tiny fraction is enough to ensure future generations of fish for anglers to catch. However, there are special situations where waters or fish or anglers need a boost from hatcheries.

Trout are a good example. Although we have rivers cool enough to support trout, only a few state streams have self-sustaining populations of rainbow trout. Brown trout are unable to reproduce here. Much of the great trout fishing we have in Missouri and millions of the dollars of economic activity generated by trout fishing annually depend on Conservation Department hatcheries.

Cold-water hatcheries

The department maintains five cold-water hatcheries to keep anglers supplied with trout. Four of the hatcheries are at trout parks. The fifth, and largest, cold-water hatchery is located on the south edge of Branson, next to the upper portion of Lake Taneycomo.

The cold-water hatcheries stock about 1.5 million trout into Missouri waters each year. Most of those fish are of catchable size—at least 10 inches long.

Raising trout to that size is a monumental job. The trout start out as tiny eggs taken in the spring or fall from brood stock at the hatchery. After the eggs hatch, the young fish have to be fed up to 12 times a day. During the 15 to 18 months before they are released, the trout need to be kept well-oxygenated, well-fed and disease-free.

Shepherd of the Hills Hatchery accomplishes this task with the help of eight full-time employees. The hatchery workers monitor the automatic systems that track temperatures and oxygen levels, feed and grade the trout, and transport them from place to place among the facility’s 36 raceways.

The hatchery is fueled by cold water taken from 140 feet down in Table Rock Lake at the rate of 10,000 gallons a minute. Well water is mixed in to obtain optimum temperatures. Ultraviolet systems help control bacterial diseases that, left uncontrolled, could kill all the fish.

This care results in a good product. Civiello said that Shepherd of the Hills expects 80 percent of the eggs they fertilize to hatch and about 85 percent of the fry to grow to a releasable size.

The fish are stocked at rates and locations requested by fisheries management biologists. The five separate hatcheries work as a unit to fulfill trout requests around the state. For example, Shepherd of the Hills might supply eggs or fish to Montauk or Bennett Springs, and Roaring River might temporarily store fish from another hatchery.

“It’s possible,” said Kevin Richards, chief of the Ozark unit fisheries field operations, “for an angler at a trout park to take a fish that has spent time at three or even four hatcheries. That’s how well the hatcheries work together as a system.”

Conservation Department hatchery trucks make hundreds of delivery runs each year throughout the state. Just to stock a half million fish in Taneycomo each year requires more than 180 trips. Fish are probably the most fragile when they are in the hatchery trucks. To get the fish to their destinations in good shape, hatchery personnel have to take into account the distance, the temperature, the capacity of the truck and the amount of oxygen in the water. A miscalculation could easily kill the entire load.

Although most of the trout end up at trout parks and Lake Taneycomo, some of them are distributed to urban lakes in the fall to provide close-to-home fishing opportunities for city residents.

Thanks to our cold-water hatcheries, trout fishing is already great in Missouri, but it will soon be better.

The Conservation Department’s “A Plan for Missouri Trout Fishing” calls for maintenance and improvement projects that will enable the state’s cold-water hatchery system to meet present and future demand for trout, provide a buffer against possible losses during the production process and allow an increase in the average size of trout stocked. More than 40 new infrastructure improvements will begin this winter and will continue for several years.

Warm-water hatcheries

The Conservation Department maintains five warm-water hatcheries. Like the cold-water hatcheries, the five work as an integrated unit, but each has its specialties.

Lost Valley Hatchery near Warsaw, for example, produces the bulk of the state’s walleye and white bass/striped bass hybrids, as well as catfish for the urban fishing programs. Chesapeake Hatchery near Mount Vernon is a catfish factory, while Blind Pony Hatchery near Sweet Springs raises paddlefish and endangered pallid sturgeon. Hunnewell Hatchery in Shelby County is best known for growing large hybrid sunfish for kids’ fishing clinics across the state. Indian Trail Hatchery near Salem is the source of many of the bass, bluegill and catfish that go to the state’s farm pond stocking program.

The hatcheries produce astonishing numbers of fish. Ken Neubrand, the manager of Lost Valley Hatchery, said that each year the facility raises more than 110,000 1-pound catfish, up to 900,000 young walleye and from 300,000 to 600,000 hybrid striped bass.

One way to tell a warm-water hatchery from a coldwater hatchery is that the former is likely to keep fish in ponds. The other difference is that warm-water hatcheries deal with many different species of fish.

Neubrand said that for each species of fish, the production process is generally the same. “We’re collecting brood stock, we’re getting eggs out of brood stock and creating young fish that we put into our ponds and grow to acceptable size before taking them out to lakes to stock.”

Lost Valley hatchery is one of the largest and most modern fish factories in the nation. The complex includes 78 rearing ponds interconnected by a mind-boggling array of pipes, pumps and electrical wires.

“It’s pretty high-tech,” Neubrand said. “We have a computer monitoring system that monitors the wells, which are our main water source. It monitors the towers and the water flow through about 15 miles of pipe.”

Hatchery fish at work

Fish from warm-water hatcheries often seed self-sustaining fisheries. The highly popular Private Pond and Lake Fish Stocking Program is a good example. Conservation Department hatcheries raise largemouth bass, bluegill and channel catfish and provide them to landowners without charge to establish fisheries in new or renovated private ponds and lakes.

The hatcheries also provide fish for new or renovated public lakes. In fact, the Conservation Department fisheries division constantly looks for opportunities to establish, enhance or restore popular fish species in all the state’s 890 public lakes.

Visiting Hatcheries

Shepherd of the Hills and Lost Valley hatcheries attract thousands of visitors each year. You and your family can learn all about raising fish and see huge fish up close. Guided tours are available.

Both hatcheries are open to visitors year-round, except for Thanksgiving, Christmas and New Year’s Day. Lost Valley is closed on Sundays and Mondays from Labor Day until April 30.

Lost Valley Hatchery is northeast of Warsaw at the Truman Dam access road. Call (660) 438-4465 for more information.

Shepherd of the Hills Hatchery is located on Highway 165, below the dam at Table Rock Lake. Call (417) 334-4865 for ore information.

Sometimes this means introducing species, such as redear sunfish. Sometimes it means rebalancing a lake’s fish population by introducing predator species, such as muskie and hybrid striped bass.

The hatcheries are also experimenting with raising endangered species. Lost Valley and Chesapeake hatcheries, for example, have propagated several species of endangered mussels, and Lost Valley successfully raised endangered Topeka shiners. Blind Pony is the first state hatchery in the country to have successfully spawned pallid sturgeon.

No matter what species of fish are involved, hatchery work is as relentless as a factory production line. Every day, hatchery workers have to feed, treat, grade, stock, tag, transport, monitor and inventory fish. Planning for fish production and distribution has to take place months or even years in advance.

It’s probably the furthest thing from your mind when you’re out on the water fishing, but that tug you feel at the end of your line is the result of lots of hard work, dedication and good management.

And More...

This Issue's Staff

Managing Editor - Nichole LeClair

Art Editor - Ara Clark

Artist - Dave Besenger

Artist - Mark Raithel

Photographer - Jim Rathert

Photographer - Cliff White

Staff Writer - Jim Low

Staff Writer - Joan McKee

Circulation - Laura Scheuler